Hydraulic dredging has emerged as a cornerstone technology for marine and industrial operations, playing a pivotal role in maintaining navigable waterways, extracting valuable materials, and restoring ecosystems. Unlike traditional mechanical methods, hydraulic dredging relies on the power of water to transport sediment and materials, offering a more efficient and versatile solution for a wide range of applications, from harbor maintenance to land reclamation and environmental restoration projects. The hydraulic dredging process involves using specialized equipment to agitate and transport sediment from the seabed, riverbed, or other underwater environments. This process not only helps to maintain critical infrastructure, such as ports and shipping channels but also supports industries like mining and energy production. By employing state-of-the-art hydraulic dredging equipment, operators can achieve faster sediment removal, enhanced precision, and reduced environmental impact, making it an indispensable tool for modern dredging operations.

As global demand for efficient and sustainable dredging solutions continues to rise, the industry is witnessing a technological transformation. Innovations in pump design, automation, and real-time monitoring systems are revolutionizing the hydraulic dredging process, enabling higher levels of efficiency and environmental stewardship. Embracing these advancements is not just an opportunity but a necessity for companies looking to stay competitive in an increasingly complex and regulated market. In this blog, we delve into the latest innovations in hydraulic dredging equipment and explore how these advancements are shaping the future of the industry.

What is Hydraulic Dredging?

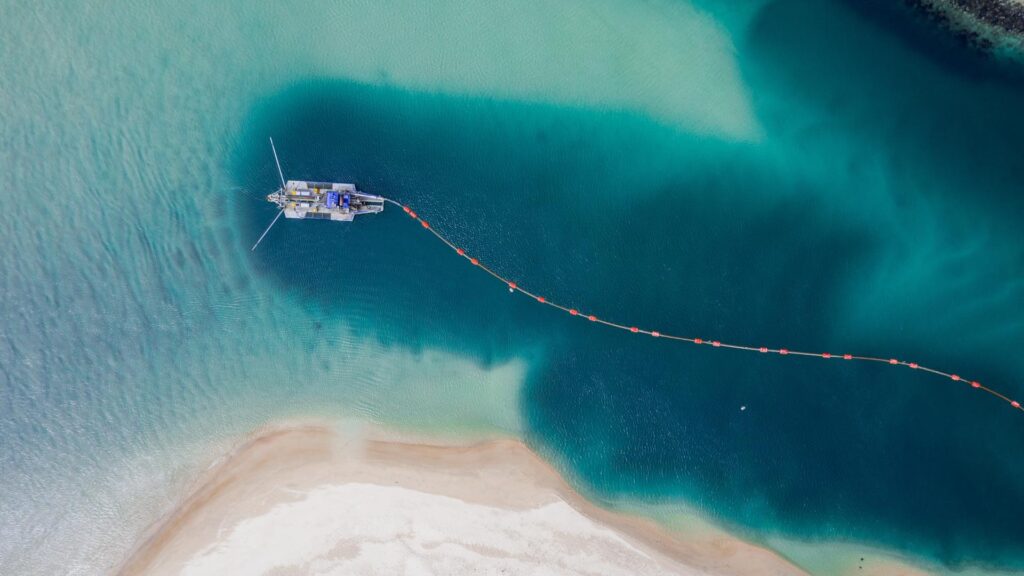

Hydraulic dredging is a highly effective method for excavating and transporting sediment, sand, silt, or other materials from underwater environments such as riverbeds, lakes, harbors, and coastal areas. Unlike mechanical dredging, which relies on buckets or clamshells to remove material, hydraulic dredging uses water flow and suction to loosen and transport sediment through pipelines. Thus, it is a versatile and efficient solution for a variety of marine and industrial operations.

Hydraulic dredging’s purpose extends beyond simple sediment removal. It is a critical tool for maintaining navigable waterways, facilitating port operations, preventing flooding, and restoring ecological habitats. By efficiently removing accumulated sediment, hydraulic dredging ensures the functionality of harbors, shipping channels, and reservoirs, supporting industries ranging from maritime trade to environmental restoration.

An Overview of the Hydraulic Dredging Process

The hydraulic dredging process begins with specialized hydraulic dredging equipment, such as cutter suction dredgers or plain suction dredgers, which are designed to agitate and remove sediment from underwater surfaces. The process involves the following steps:

- Sediment Agitation: Dredging equipment, often equipped with a cutter head or jetting nozzles, loosens sediment from the seabed or riverbed.

- Suction and Transportation: A powerful pump creates a water-sediment mixture (slurry) that is transported through pipelines to a designated location, such as a disposal site or reclamation area.

- Discharge: The transported material is discharged for use in land reclamation, beach nourishment, or other purposes or safely deposited to prevent environmental harm.

This process is highly adaptable and can handle a range of sediment types and project scales, from small-scale environmental restoration to large-scale port expansions.

Applications of Hydraulic Dredging

Hydraulic dredging has diverse applications across various industries, including:

- Port Maintenance: Regular dredging ensures that shipping channels and harbors remain deep enough for safe navigation, enabling the smooth flow of global trade.

- Mining Operations: In the mining industry, hydraulic dredging is used to extract valuable materials such as sand, gravel, and minerals from underwater deposits.

- Environmental Restoration: Dredging is employed to remove contaminated sediment, restore wetlands, and improve water quality in rivers and lakes.

- Flood Control: Hydraulic dredging removes sediment buildup, helping to manage water flow and prevent flooding in rivers and reservoirs.

- Land Reclamation: Dredged material is often used to create new land areas, expand coastlines, or rebuild eroded beaches.

The Importance of Hydraulic Dredging in Addressing Modern Challenges

In today’s world, challenges such as sediment management, climate change, and environmental degradation make hydraulic dredging more essential than ever. Sediment buildup can disrupt ecosystems, impede water flow, and compromise infrastructure. Hydraulic dredging mitigates these issues and offers sustainable solutions for waterway restoration and habitat preservation.

Modern advancements in hydraulic dredging equipment allow for more precise and environmentally friendly operations. These operations reduce ecological impacts while meeting the growing demands of industrial and environmental projects. By addressing these challenges, hydraulic dredging plays a pivotal role in balancing economic growth with environmental sustainability, ensuring the continued functionality of vital waterways and ecosystems.

Evolution of Hydraulic Dredging Technology

Hydraulic dredging has a rich history rooted in the need to manage waterways, support maritime trade, and reclaim land. Over the years, technological advancements have transformed this essential process, making it more efficient, precise, and environmentally sustainable. The evolution of hydraulic dredging equipment has played a key role in meeting the growing demands of industries such as port management, mining, and environmental restoration.

A Brief History of Hydraulic Dredging

Dredging has existed for centuries, with early methods relying on manual labor and rudimentary tools. Mechanical dredging gained prominence in the 19th century with the introduction of steam-powered dredgers, which revolutionized sediment removal and transport. However, these systems were limited by their labor-intensive nature and inefficiency in handling large-scale projects.

Hydraulic dredging emerged as an innovative alternative in the late 19th and early 20th centuries. By harnessing the power of water and suction, this method allowed for faster sediment transport over longer distances. Early hydraulic dredgers relied on basic pumps and pipelines to move sediment, laying the foundation for the sophisticated equipment we use today.

Key Milestones in Dredging Innovations

The evolution of hydraulic dredging technology has been marked by several significant milestones that have improved efficiency, scalability, and environmental performance:

- Advancements in Dredge Pumps:

- The development of high-capacity pumps allowed for more effective sediment suction and transport. Modern dredge pumps are designed to handle a wide range of sediment types, from fine silt to coarse gravel, with minimal wear and tear.

- Variable-speed and energy-efficient pumps have further optimized the hydraulic dredging process, reducing operational costs and environmental impact.

- Pipeline Technology:

- Innovations in pipeline materials and design have extended the reach of hydraulic dredging operations. Lightweight and durable materials, such as high-density polyethylene (HDPE), ensure efficient sediment transport over long distances with minimal leakage or degradation.

- Flexible pipelines and floating hose systems have enhanced the adaptability of dredging equipment to various terrains and water depths.

- Automation and Control Systems:

- The integration of automation in hydraulic dredging equipment has significantly improved precision and operational efficiency. Advanced control systems allow operators to monitor and adjust dredging parameters in real-time, ensuring optimal performance.

- GPS and sonar technologies have enabled precise positioning and mapping of dredging areas, reducing over-dredging and minimizing environmental disruption.

- Eco-Friendly Innovations:

- The introduction of environmentally conscious designs, such as biodegradable hydraulic fluids and sediment containment systems, has reduced dredging projects’ ecological footprints.

- Hybrid systems that combine mechanical and hydraulic processes have further improved efficiency while adhering to stricter environmental regulations.

The Shift from Mechanical to Hydraulic Systems

The transition from mechanical to hydraulic dredging marked a turning point in the industry. Mechanical dredging, which relies on physical excavation tools like buckets and clamshells, is effective for small-scale or highly specific projects but is limited in scalability and efficiency.

Hydraulic dredging, on the other hand, uses water flow to agitate, transport, and deposit sediment, offering numerous advantages:

- Higher Efficiency: Hydraulic systems can move larger volumes of sediment more quickly and over greater distances than mechanical systems.

- Scalability: Hydraulic dredging equipment is adaptable to projects of all sizes, from small environmental cleanups to massive port expansions.

- Reduced Labor Requirements: Automation and advanced technologies reduce the need for manual labor, improving safety and cost-effectiveness.

- Environmental Benefits: Hydraulic systems disturb less of the surrounding environment compared to mechanical dredging, making them ideal for projects in sensitive ecological areas.

The shift to hydraulic systems has also enabled the industry to tackle modern challenges, such as climate change and sediment management, with greater precision and sustainability.

Modern Innovations in Hydraulic Dredging Equipment

The field of hydraulic dredging has experienced rapid advancements in recent years, driven by the need for greater efficiency, precision, and environmental responsibility. Cutting-edge technologies have transformed hydraulic dredging equipment, enabling it to meet the increasing demands of industrial and environmental projects while minimizing its ecological footprint. These modern innovations are shaping the future of the hydraulic dredging process, making it more effective and sustainable than ever before.

1. Advances in Dredge Pumps

The dredge pump is a critical component of the hydraulic dredging process, transporting sediment and water through pipelines. Modern dredge pumps have undergone significant improvements, resulting in enhanced performance and reduced operational costs.

- High-Efficiency Designs:

New-generation dredge pumps feature improved impeller designs and advanced materials that minimize wear and tear, especially when handling abrasive sediments like sand and gravel. These high-efficiency pumps reduce energy consumption, making the hydraulic dredging process more cost-effective and eco-friendly. - Variable-Speed Technology:

Variable-speed pumps allow operators to adjust the pump’s power output based on the sediment type and project requirements. This flexibility not only optimizes performance but also extends the lifespan of the pump by reducing unnecessary strain. - Self-Priming Pumps:

The development of self-priming dredge pumps eliminates the need for external priming systems, simplifying operations and reducing setup times.

These advancements have made dredge pumps more reliable and capable of handling larger volumes of sediment, significantly improving the efficiency of the overall dredging process.

2. Integration of Real-Time Monitoring Systems

One of the most transformative innovations in hydraulic dredging equipment is the integration of real-time monitoring systems. These systems leverage advanced sensors, GPS, and data analytics to provide operators with accurate, real-time information about the dredging operation.

- Enhanced Precision:

Real-time data on sediment density, flow rates, and pump performance allows operators to make immediate adjustments, ensuring optimal dredging efficiency and minimizing material waste. - GPS and Sonar Mapping:

Advanced positioning systems enable precise mapping of dredging areas, reducing over-dredging and ensuring compliance with project specifications. These technologies are particularly valuable for environmental restoration projects, where precision is critical to avoid disturbing sensitive ecosystems. - Predictive Maintenance:

Monitoring systems can also track the condition of dredging equipment, identifying potential issues before they lead to costly downtime. Predictive maintenance reduces repair costs and improves project timelines, making operations more reliable and efficient.

By integrating these systems into hydraulic dredging operations, companies can achieve greater accuracy, reduce operational risks, and enhance overall productivity.

3. Development of Eco-Friendly Dredging Solutions

As environmental regulations become stricter, the dredging industry has embraced eco-friendly innovations to minimize its impact on natural ecosystems. These advancements in hydraulic dredging equipment are helping to align dredging practices with sustainability goals.

- Energy-Efficient Equipment:

Modern dredgers are equipped with energy-efficient engines and pumps that consume less fuel, reducing greenhouse gas emissions. Hybrid systems that combine traditional power sources with renewable energy are also being explored. - Biodegradable Hydraulic Fluids:

The use of biodegradable and non-toxic hydraulic fluids in dredging equipment prevents harmful chemicals from leaking into aquatic environments, safeguarding water quality and marine life. - Sediment Containment Systems:

Innovative containment solutions, such as geotextile tubes and silt curtains, secure the management of dredged material and prevent sediment plumes from spreading and affecting nearby ecosystems. - Noise Reduction Technology:

Advances in equipment design have also reduced underwater noise pollution, protecting marine species that rely on sound for communication and navigation.

These eco-friendly innovations not only meet regulatory requirements but also enhance the reputation of dredging companies as environmentally responsible operators.

The Impact of Modern Innovations

The combination of advanced dredge pumps, real-time monitoring systems, and eco-friendly technologies is revolutionizing the hydraulic dredging process. These innovations are enabling dredging companies to:

- Achieve higher levels of efficiency and precision.

- Reduce costs through energy savings and predictive maintenance.

- Minimize environmental impact and comply with increasingly stringent regulations.

Automation and Artificial Intelligence in Hydraulic Dredging

The adoption of automation and artificial intelligence (AI) is driving a paradigm shift in the hydraulic dredging industry, revolutionizing operations’ planning, execution, and monitoring. By integrating cutting-edge technologies, hydraulic dredging processes are becoming faster, more precise, and cost-efficient while minimizing environmental impacts and operational risks. Automation and AI have transformed everything from equipment operation to decision-making, paving the way for a more innovative and sustainable future.

How Automation is Revolutionizing Hydraulic Dredging Processes

Automation is redefining the efficiency and reliability of hydraulic dredging equipment. With advanced sensors, control systems, and machine learning algorithms, dredging operations are becoming smarter and less reliant on human intervention. Some of the most significant advancements include:

1. Autonomous Dredging Vessels

Autonomous dredging vessels are among the most groundbreaking innovations in the hydraulic dredging industry. These vessels are equipped with sophisticated navigation systems, sensors, and onboard control units that allow them to operate with minimal or no human input.

- Precision Operations: Autonomous vessels utilize GPS, LiDAR, and sonar technologies to precisely locate and remove sediment, ensuring efficient dredging without over-dredging or disturbing surrounding areas.

- Increased Efficiency: With continuous operation capabilities, autonomous dredgers can work around the clock, significantly reducing project timelines.

- Safety Benefits: These vessels minimize the risks associated with hazardous working environments, such as rough waters or contaminated sediment, by reducing the need for onboard personnel.

For example, autonomous dredgers are already being deployed in ports and waterways to maintain channel depths and improve shipping efficiency.

2. AI-Powered Decision-Making for Sediment Removal Efficiency

Artificial intelligence plays a crucial role in optimizing the hydraulic dredging process. It analyzes data and makes real-time decisions to enhance operational performance.

- Real-Time Data Analysis: AI systems process data from sensors, such as sediment density, water flow, and pump pressure, to adjust dredging parameters in real time. This ensures maximum efficiency and reduces unnecessary energy consumption.

- Predictive Modeling: AI can analyze historical and environmental data to predict sediment accumulation patterns, helping operators plan more effective dredging strategies.

- Intelligent Sediment Management: AI-powered systems determine the optimal locations for sediment discharge or reuse, improving material handling and minimizing environmental impact.

The integration of AI not only streamlines operations but also ensures sustainable practices by reducing waste and energy consumption.

Advantages of Automation in Reducing Operational Risks and Costs

Automation offers significant benefits that address some of the key challenges faced in hydraulic dredging:

- Reduced Human Error: Automated systems eliminate the risk of errors caused by fatigue or misjudgment, ensuring consistent and precise operations.

- Lower Operational Costs: Automation lowers overall project costs by optimizing fuel consumption, reducing downtime, and minimizing the need for manual labor.

- Enhanced Safety: Automated dredgers and AI systems reduce the need for human workers to operate in hazardous environments, improving workplace safety.

- Improved Equipment Longevity: Automation and predictive maintenance systems ensure equipment is used efficiently, reducing wear and tear and extending the lifespan of hydraulic dredging equipment.

Future Potential: Fully Autonomous Dredging Operations

The future of hydraulic dredging lies in fully autonomous operations. While automation is already making significant strides, advancements in AI and robotics are expected to unlock even greater possibilities:

- Self-Learning Dredgers: AI-powered dredgers capable of learning from past operations to continuously improve performance and efficiency.

- Swarm Dredging Systems: Networks of smaller, autonomous dredgers working collaboratively to handle large-scale projects with unprecedented precision and speed.

- Remote Monitoring and Control: Operators will be able to oversee and manage dredging projects from centralized control centers, even in remote locations, using real-time data and advanced visualization tools.

- Sustainability Enhancements: Autonomous systems will integrate eco-friendly practices, such as precision dredging and minimal sediment disturbance, to align with global sustainability goals.

The transition to fully autonomous dredging operations will redefine the industry. It will enable large-scale projects to be completed with minimal human involvement, reduced costs, and minimal environmental impact.

Data-Driven Hydraulic Dredging

The integration of data-driven technologies has revolutionized the hydraulic dredging process, enabling operators to achieve higher precision, efficiency, and sustainability. IoT (Internet of Things) sensors, predictive maintenance powered by machine learning, and the application of big data analytics are transforming how dredging projects are planned and executed.

Use of IoT Sensors in Monitoring Dredging Parameters

IoT sensors are crucial for monitoring dredging operations in real-time. They are providing actionable data on key parameters such as sediment density, flow rate, pump performance, and water quality.

- Improved Precision: IoT sensors installed on hydraulic dredging equipment continuously collect and transmit data, allowing operators to fine-tune processes for optimal sediment removal.

- Enhanced Efficiency: By monitoring flow rates and pump performance, IoT devices ensure that the dredging process remains energy-efficient and cost-effective.

- Environmental Compliance: Sensors track water quality and turbidity levels, ensuring that dredging activities adhere to environmental regulations and minimize ecological disruption.

Predictive Maintenance Using Machine Learning

Machine learning algorithms analyze vast amounts of data from IoT sensors to predict equipment wear and potential failures.

- Reduced Downtime: Predictive maintenance schedules repairs before breakdowns occur, ensuring uninterrupted dredging operations.

- Cost Savings: Early detection of issues prevents expensive repairs and extends the lifespan of hydraulic dredging equipment.

- Operational Efficiency: By maintaining equipment in peak condition, predictive maintenance minimizes delays and improves project timelines.

Impact of Big Data on Project Planning and Execution

Big data analytics is reshaping how dredging projects are designed and executed.

- Optimized Planning: Historical and real-time data on sediment accumulation, tidal patterns, and environmental conditions help operators plan more efficient dredging routes and schedules.

- Improved Decision-Making: Data-driven insights enable precise adjustments to the dredging process, ensuring better resource management and reduced operational costs.

- Sustainability Goals: Big data supports environmentally responsible dredging by identifying areas where sediment removal can have the least ecological impact.

Sustainability in the Hydraulic Dredging Process

The focus on sustainability in hydraulic dredging has led to the adoption of innovative technologies and eco-friendly practices. Energy-efficient equipment, biodegradable materials, and adherence to strict environmental regulations are reshaping the industry’s approach to balancing economic and environmental goals.

Energy-Efficient Dredge Pumps

Advancements in dredge pump technology have significantly reduced energy consumption during the hydraulic dredging process.

- Optimized Designs: High-efficiency impellers and variable-speed pumps reduce energy waste, making dredging operations more cost-effective and environmentally friendly.

- Hybrid Systems: Combining traditional power sources with renewable energy options, such as solar or wind, further enhances the sustainability of hydraulic dredging equipment.

Use of Biodegradable Hydraulic Fluids in Equipment

The transition to biodegradable hydraulic fluids has minimized the environmental risks associated with equipment leaks.

- Eco-Friendly Operations: Non-toxic fluids prevent contamination of marine ecosystems, protecting water quality and aquatic life.

- Regulatory Compliance: Biodegradable fluids help dredging companies meet stringent environmental regulations, enhancing their reputation as responsible operators.

Regulations Shaping the Future of Sustainable Hydraulic Dredging

Governments and regulatory bodies are implementing stricter standards for dredging activities to ensure minimal environmental impact.

- Emission Standards: Regulations limiting greenhouse gas emissions are driving the adoption of cleaner and more efficient dredging technologies.

- Habitat Protection: Guidelines on sediment containment and disposal ensure the protection of sensitive ecosystems during dredging operations.

Role of Technology in Balancing Economic and Environmental Goals

Innovative technologies enable the hydraulic dredging industry to achieve sustainability without compromising economic viability.

- Precision Dredging: Advanced equipment reduces material waste and energy use, lowering costs while protecting ecosystems.

- Data-Driven Solutions: Real-time monitoring and analytics optimize resource allocation, ensuring economic efficiency and environmental compliance.

Future Trends in Hydraulic Dredging Technology

As technology continues to evolve, groundbreaking innovations in materials, equipment, and methodologies will benefit the hydraulic dredging process.

Emerging Materials for Lightweight, Durable Equipment

- Composite Materials: The use of lightweight composites in dredging equipment reduces fuel consumption and enhances mobility.

- Corrosion-Resistant Alloys: Advanced materials improve the durability and lifespan of dredge pumps, pipelines, and other components.

Next-Generation Pumps for Increased Efficiency and Reduced Downtime

- Energy-Efficient Designs: Next-generation pumps are designed to handle higher sediment loads with minimal energy use, improving overall efficiency.

- Self-Cleaning Systems: Pumps equipped with self-cleaning mechanisms reduce clogging, ensuring consistent operation and fewer interruptions.

Hybrid Dredging Systems Combining Mechanical and Hydraulic Processes

- Versatility: Hybrid systems combine the strengths of mechanical and hydraulic dredging, allowing operators to tackle a wider range of projects.

- Improved Efficiency: Hybrid systems integrate the two processes to achieve better sediment removal rates and reduce overall project costs.

Potential Breakthroughs in Underwater Robotics for Dredging Operations

- Autonomous Robots: Underwater robots equipped with AI and advanced sensors can perform targeted sediment removal with unmatched precision.

- Maintenance Drones: Robotic systems designed for underwater inspection and repair ensure that dredging equipment remains in peak condition.

8. Benefits of Technological Advancements in Hydraulic Dredging

The adoption of modern technologies in hydraulic dredging equipment delivers numerous benefits, revolutionizing the industry and addressing its most pressing challenges.

Enhanced Efficiency and Reduced Costs

- Advanced equipment and automation minimize operational inefficiencies, lowering fuel consumption and labor costs.

- Real-time monitoring systems enable precise adjustments, improving project outcomes while reducing material waste.

Improved Project Timelines and Resource Management

- Predictive maintenance and data-driven planning streamline operations, ensuring faster project completion.

- Optimized resource allocation reduces delays and maximizes equipment utilization.

Mitigating Risks and Ensuring Worker Safety

- Automation and robotics reduce the need for human involvement in hazardous environments, minimizing risks to workers.

- Predictive analytics identify potential equipment failures before they occur, preventing accidents and costly downtime.

Conclusion

The hydraulic dredging industry stands at the forefront of innovation, leveraging advanced technologies to improve efficiency, sustainability, and safety. From IoT sensors and AI-powered systems to eco-friendly practices and next-generation equipment, these advancements are transforming the hydraulic dredging process and redefining the industry’s potential. As the future unfolds, continued investment in technological progress will enable hydraulic dredging to meet the challenges of an evolving world while delivering sustainable, cost-effective solutions.