Maintenance dredging is the routine removal of sediments, such as silt, sand, and organic matter, that naturally accumulate in waterways due to tidal movements, currents, storms, and runoff. This process plays a critical role in preserving the depth and navigability of channels, ports, marinas, and coastal areas. Without consistent maintenance dredging, sediment buildup can obstruct vessel movement, disrupt marine infrastructure, and negatively impact water quality and ecological balance.

Unlike capital dredging, which is carried out to create new navigation channels or expand existing ones, maintenance dredging focuses on preserving the designed depth and functionality of already-established water bodies. It is a recurring necessity in areas affected by high sedimentation, particularly in coastal zones and busy ports. From harbor dredging operations that ensure safe passage for commercial vessels to beach reclamation efforts that restore eroded shorelines, maintenance dredging is a foundational practice that supports both economic activity and environmental sustainability.

This blog explores the most effective strategies and industry-recommended practices to carry out maintenance dredging in a way that maximizes efficiency, minimizes environmental disruption, and meets regulatory compliance.

Why Maintenance Dredging is Critical

Maintaining safe and reliable access to navigable waterways is one of the primary reasons maintenance dredging is essential. Over time, natural processes such as tidal shifts, river currents, and stormwater runoff deposit sediments in harbors, rivers, and coastal inlets. These accumulations gradually reduce water depth, creating hazards for commercial and recreational vessels. Routine dredging ensures that these critical routes remain navigable, reducing the risk of vessel groundings and enabling uninterrupted maritime traffic.

In areas with high vessel activity, especially those requiring precise draft tolerances, harbor dredging becomes a vital component of port management. Dredging prevents sediment from obstructing berths, piers, and turning basins, which are critical to port logistics and docking operations. Similarly, inlets and channels connecting inland waterways to the ocean must be regularly cleared to maintain their functional width and depth.

Beyond navigation, maintenance dredging plays a key role in shoreline preservation and infrastructure resilience. Coastal infrastructure—such as seawalls, piers, and breakwaters—relies on stable sediment levels to function effectively. When erosion or sediment displacement occurs, it can compromise structural integrity and increase vulnerability to storm surges. Moreover, in coastal restoration projects, dredged materials are often repurposed for beach reclamation, helping rebuild eroded shorelines and improve storm defense while supporting habitat restoration and recreational access.

Common Challenges in Maintenance Dredging

While essential for safe and functional waterways, maintenance dredging presents a number of operational and environmental challenges that must be carefully managed. One of the most common technical issues is sediment resuspension, which can significantly increase water turbidity during dredging operations. Excess turbidity not only reduces visibility but can also harm aquatic life by smothering benthic habitats and disrupting photosynthesis in submerged vegetation. Effective turbidity control measures—such as silt curtains, staged dredging, and real-time monitoring—are critical to maintaining compliance and protecting sensitive environments, particularly in beach reclamation and nearshore restoration projects.

Weather conditions and seasonal timing also pose frequent disruptions to maintenance dredging operations. Heavy rainfall, strong currents, or high winds can halt dredging activities and delay project timelines. In colder climates, ice formation can further limit access to dredging zones during winter months. Planning around favorable seasonal windows is especially important in harbor dredging, where operational delays can affect port schedules and shipping routes.

Balancing the immediate need for sediment removal with long-term environmental compliance is another persistent challenge. Dredging in ecologically sensitive areas often requires strict adherence to regulatory limits on turbidity, noise, and sediment disposal. Obtaining permits, conducting environmental impact assessments, and following mitigation protocols can be time-consuming but are necessary for legal and sustainable operations.

Additionally, conducting maintenance dredging in active harbor zones demands detailed coordination with maritime traffic control authorities. Ports often operate around the clock, and dredging must be scheduled to minimize disruption to cargo handling, docking, and vessel navigation. This logistical complexity requires clear communication, real-time tracking, and flexible work schedules to avoid interfering with port operations while still achieving the dredging goals.

Pre-Dredging Best Practices

Successful maintenance dredging operations begin with thorough site assessments and hydrographic surveys. Accurate bathymetric mapping helps define current depth profiles and pinpoints high-siltation areas where sediment has accumulated beyond acceptable limits. These surveys provide the data needed to plan the extent and method of dredging, ensuring efficiency and minimizing unnecessary disturbance. In high-traffic harbor dredging zones, regular hydrographic updates are essential to keep navigation channels, turning basins, and berths at their designated depths.

In addition to depth analysis, sediment sampling is a key component of pre-dredging evaluation. By analyzing sediment composition and potential contamination levels, dredging teams can determine the most suitable removal technique and assess whether the material is safe for open water disposal or can be repurposed for projects such as beach reclamation. Testing for pollutants or heavy metals ensures compliance with environmental standards and guides the selection of appropriate containment or disposal methods.

Before any physical dredging begins, obtaining the necessary permits and environmental clearances is a legal and operational priority. Depending on the region, this may involve federal, state, or municipal agencies with oversight of water quality, marine life protection, and shoreline management. For instance, harbor dredging projects often fall under strict marine traffic and ecological regulations. Engaging local authorities early in the planning process helps streamline permit approvals, reduce delays, and foster transparency with stakeholders. Clear documentation and proactive communication are essential to align dredging plans with regulatory expectations and ensure the project remains compliant throughout its lifecycle.

Selecting the Right Equipment for Maintenance Dredging

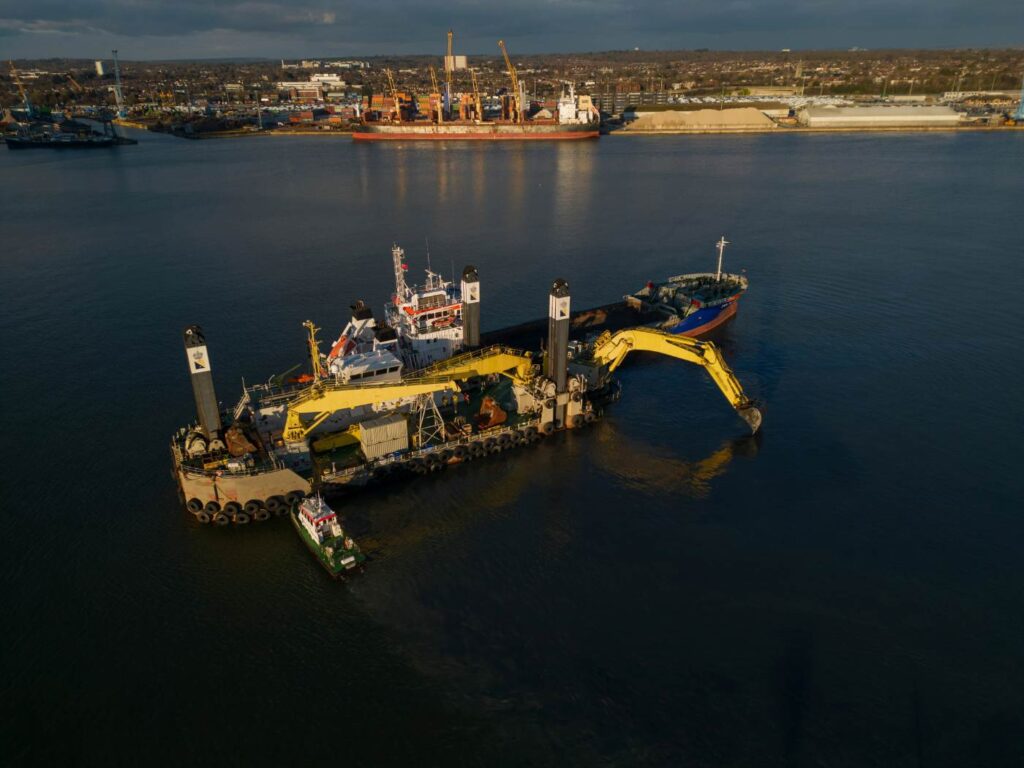

Choosing the right dredging equipment is critical to the success and efficiency of any maintenance dredging project. Different dredge types are designed for specific applications, and selecting the appropriate system depends on a variety of factors, including sediment composition, waterbody depth, and environmental sensitivity. Cutter suction dredgers are well-suited for compact or consolidated material and are commonly used in confined areas such as canals or industrial ports. Trailing suction hopper dredgers, on the other hand, are ideal for larger-scale operations with softer sediments, often employed in open coastal or offshore environments. For shallow or narrow zones, excavator-mounted dredge systems offer flexibility and precision, especially in projects involving limited access or complex shoreline conditions.

When planning a maintenance dredging operation, equipment selection must be aligned with site-specific characteristics. Water depth, current strength, wave conditions, and sediment type all influence which dredging method will be most effective and least disruptive. For instance, fine sediments with high organic content may require low-turbidity dredging methods to minimize environmental impact, while coarser materials may call for more robust mechanical removal techniques. The selected dredge must also be compatible with site logistics, including mobilization constraints, fuel availability, and access to sediment disposal or reuse sites.

Specialized equipment is especially important in harbor dredging and beach reclamation projects. Harbors often require compact yet powerful dredgers capable of maneuvering in tight berthing areas without interfering with maritime traffic. In beach restoration projects, dredging systems must support accurate sediment placement and controlled discharge to rebuild eroded shorelines without damaging nearby ecosystems. Using purpose-built tools designed for these specific applications ensures optimal performance, regulatory compliance, and minimal environmental disturbance.

Operational Best Practices

Efficient and environmentally responsible maintenance dredging requires precise timing and scheduling to align with natural and operational variables. Planning dredging activities around seasonal patterns—such as periods of low rainfall or minimal biological activity—helps reduce environmental impact. Similarly, aligning operations with tidal cycles ensures optimal sediment removal and reduces fuel consumption, especially in coastal areas. In high-traffic harbor dredging zones, scheduling must also consider vessel movements and port operations to minimize disruption and enhance safety for both dredging crews and maritime traffic.

To reduce ecological impact, dredging teams must adopt low-disturbance techniques that manage sediment release and minimize turbidity. Common strategies include deploying silt curtains to contain suspended solids, regulating pump discharge rates, and operating at reduced speeds in sensitive zones. These methods help limit sediment plumes, prevent the smothering of benthic habitats, and support compliance with environmental guidelines. In beach reclamation projects, precise sediment placement and controlled material flow are equally important to ensure shoreline restoration without damaging nearby marine ecosystems.

Real-time monitoring plays a vital role in adaptive dredging operations. By utilizing GPS positioning, sonar mapping, and turbidity sensors, operators can closely track dredger performance and environmental conditions throughout the project. These tools enable immediate adjustments to equipment settings or operational techniques in response to changing site dynamics, enhancing the accuracy and safety of the maintenance dredging process. Whether for harbor dredging or coastal restoration, real-time data ensures continuous compliance and more efficient dredging cycles.

Sediment Management and Disposal

An essential component of maintenance dredging is the responsible management and disposal of dredged sediment. The chosen disposal method must align with environmental regulations, sediment characteristics, and project objectives. Common options include offshore disposal, where sediment is transported and released in designated ocean sites; confined disposal facilities (CDFs), which are engineered areas for containing potentially contaminated or unsuitable material; and upland reuse, where clean sediment is repurposed for agricultural, construction, or landscaping use.

The proper evaluation of dredged material is crucial before determining its final destination. Sediment testing assesses grain size, organic content, and potential contaminants such as heavy metals or hydrocarbons. Clean, uncontaminated sediment can be beneficially reused in projects like beach reclamation, where it helps rebuild eroded shorelines and buffer coastal infrastructure. Similarly, suitable material can support land creation, dune restoration, or habitat rehabilitation—offering ecological and economic value beyond its removal from the dredging site.

Compliance with environmental and legal requirements is non-negotiable throughout the sediment disposal process. Harbor dredging and coastal operations are subject to strict permitting frameworks, often requiring detailed plans for transport, placement, and long-term monitoring of dredged material. Working closely with regulatory agencies ensures that all disposal or reuse practices meet national and local standards, protecting both public waterways and nearby ecosystems while maximizing the efficiency of maintenance dredging efforts.

Post-Dredging Evaluation and Maintenance Planning

Once maintenance dredging operations are completed, post-dredging evaluation is essential to confirm project success and plan for future maintenance. Conducting updated bathymetric surveys allows dredging teams and stakeholders to verify that target depths have been achieved and that sediment has been removed uniformly across the designated area. These surveys help detect any high spots or residual shoaling that could impact vessel navigation, particularly in high-traffic harbor dredging zones where precision is critical.

Establishing benchmarks for sedimentation rates is a key part of proactive maintenance planning. By comparing pre- and post-dredging data over time, operators can determine how quickly specific areas accumulate sediment and identify patterns influenced by currents, tides, or seasonal changes. This data-driven approach supports the creation of optimized dredging schedules, reducing the need for costly emergency interventions. In beach reclamation projects, performance feedback can also assess the stability and retention of placed material, informing future shoreline reinforcement strategies.

Collecting and analyzing performance metrics over multiple dredging cycles enables continuous improvement. By evaluating equipment performance, dredging efficiency, and environmental compliance, operators can refine their methodologies and enhance the sustainability of future maintenance dredging operations. This forward-thinking approach not only improves cost efficiency but also ensures consistent, reliable results across long-term harbor and coastal management programs.

Digital Tools and Innovations in Maintenance Dredging

Technology continues to transform how maintenance dredging is planned, executed, and optimized. One of the most impactful advancements is the use of dredging management software, which enables precise planning, real-time tracking, and comprehensive reporting. These platforms integrate bathymetric data, equipment logs, and regulatory requirements, allowing project managers to streamline operations, improve accuracy, and maintain full transparency. In busy harbor dredging environments, digital tools also facilitate communication with port authorities, helping to coordinate operations with minimal disruption to maritime traffic.

Automation is another key innovation in modern dredging. Remote-controlled dredgers and autonomous platforms are increasingly being deployed for routine maintenance dredging, particularly in confined or hazardous areas. These systems reduce the need for onboard personnel, enhance safety, and offer higher operational consistency. For nearshore projects like beach reclamation, automated systems can ensure precise sediment placement, reducing environmental impact while maintaining project efficiency.

Data analytics is also playing a growing role in predictive maintenance strategies. By analyzing historical sedimentation rates, weather patterns, and vessel movement data, dredging teams can forecast when and where dredging will be required next. This predictive capability helps optimize dredging frequency, allocate resources more efficiently, and reduce long-term costs. As digital technologies continue to evolve, they are becoming essential tools for enhancing the performance, sustainability, and strategic planning of maintenance dredging operations.

Conclusion

Effective maintenance dredging is vital to preserving navigable waterways, protecting coastal infrastructure, and supporting long-term environmental sustainability. By implementing strategic best practices—from pre-dredging assessments and optimized equipment selection to real-time monitoring and sediment management—operators can ensure that dredging activities are both efficient and compliant. Whether working in high-traffic harbor dredging zones or supporting shoreline restoration through beach reclamation, a well-executed maintenance strategy helps mitigate sediment-related risks while maximizing operational continuity.

The integration of digital tools, automated systems, and data analytics is reshaping how dredging is approached, offering smarter, safer, and more cost-effective solutions. As sedimentation patterns evolve and environmental regulations tighten, adopting a proactive and technology-driven approach to maintenance dredging will be critical. By staying ahead of these challenges with a focus on planning, innovation, and sustainability, dredging professionals can ensure that marine infrastructure remains resilient and waterways remain accessible for generations to come.