Selecting and configuring the right submersible slurry pump is critical to ensuring efficient and reliable performance in demanding industrial environments. Whether you’re dealing with tailings in mining, sediment in dredging, or sludge in wastewater treatment, understanding the variables that affect pump sizing, material selection, and installation is essential. This guide breaks down the differences between electric submersible slurry pumps and hydraulic submersible slurry pumps, highlights the key sizing factors, and offers practical tips for setup, maintenance, and long-term operation. With the right knowledge, operators can avoid costly mistakes and maximize the productivity and lifespan of their slurry pumping systems.

Understanding Submersible Slurry Pumps

Definition and Functionality

A submersible slurry pump is a specialized pumping device designed to operate while fully submerged in slurry—a semi-liquid mixture of water and solid particles, often abrasive and corrosive. Unlike standard submersible pumps, which are typically used for clean or lightly contaminated water, submersible slurry pumps are engineered to handle high concentrations of solids, including sand, silt, mud, and industrial waste. These pumps are built with heavy-duty impellers, durable housing materials, and high-torque motors to withstand harsh operating environments and prevent premature wear.

The core function of a submersible slurry pump is to efficiently move viscous and abrasive fluids from one point to another while submerged. It uses high-velocity impellers to generate the force needed to suspend and transport solid-laden fluids through discharge piping. Unlike surface pumps, which require suction, submersible pumps are positioned directly in the slurry, minimizing energy loss and improving overall pump efficiency.

Both hydraulic submersible slurry pump and electric submersible slurry pump variants are available, offering flexibility depending on the site’s power availability, mobility requirements, and operating environment. Hydraulic models are often preferred in remote or mobile setups where electric power is not readily available, while electric models are ideal for fixed or industrial installations.

Applications

Submersible slurry pumps are critical across a wide range of industrial sectors where solid-liquid mixtures must be transported reliably and efficiently. These include:

- Mining and Mineral Processing – For pumping tailings, ore slurries, and dewatering mines.

- Dredging Operations – Used in both marine and inland dredging to remove sediments, silt, and debris.

- Tunneling and Construction – Essential for groundwater control, slurry wall construction, and tunnel boring operations.

- Municipal and Industrial Wastewater – Handling sludge, grit, and waste streams in treatment plants.

- Oil and Gas – Used in drilling support operations and sump pit management.

Whether opting for a hydraulic submersible slurry pump in rugged terrain or an electric submersible slurry pump in a controlled facility, selecting the right configuration ensures optimal performance in these demanding applications.

Types of Submersible Slurry Pumps

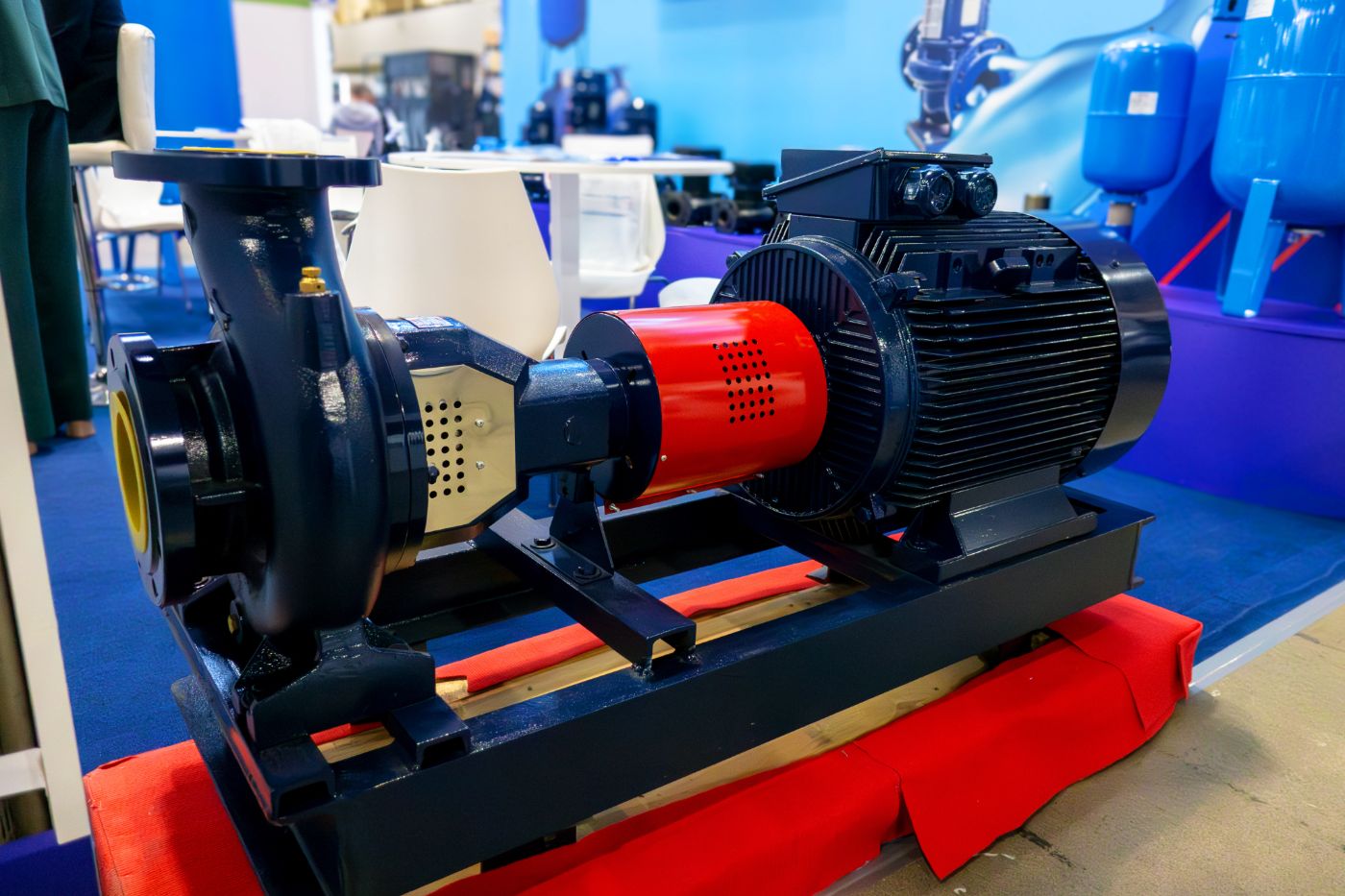

Electric Submersible Slurry Pump

An electric submersible slurry pump is powered by an integrated electric motor housed in a sealed casing, allowing it to operate fully submerged in slurry. These pumps are commonly used in fixed installations where access to consistent electrical power is available. Their compact design and ease of installation make them ideal for long-term operations in facilities such as wastewater treatment plants, mining operations, and industrial processing sites.

Use Cases:

- Tailings ponds in mining operations

- Industrial sump pits

- Wastewater treatment plants

- Controlled dredging environments

Pros:

- High efficiency for continuous operations

- Reliable performance with fewer moving parts and direct power access

- Ease of automation and remote monitoring compatibility

Cons:

- Limited mobility—requires electrical infrastructure on-site.

- Not ideal for remote locations without power access

- Potential overheating risks in low-fluid conditions if not properly monitored

Hydraulic Submersible Slurry Pump

A hydraulic submersible slurry pump is driven by hydraulic power rather than electricity. It connects to an external power pack or is integrated with heavy machinery, such as an excavator, making it highly suitable for dynamic and remote job sites. These pumps excel in harsh environments, particularly where mobility, versatility, and rugged durability are essential.

Use Cases:

- Remote dredging sites and mobile dewatering

- Excavator-mounted slurry pumping

- Oil and gas applications requiring off-grid equipment

- Emergency flood response or environmental cleanups

Pros:

- Superior mobility—ideal for mobile or excavator-mounted systems

- High power density—more compact for the same output as electric variants

- Excellent compatibility with other hydraulic equipment on construction or mining sites

Cons:

- Requires a hydraulic power pack or a machinery interface

- Higher maintenance due to hydraulic fluid and connections

- More complex setup compared to plug-and-play electric models

When to Choose Which Type

Choosing between an electric submersible slurry pump and a hydraulic submersible slurry pump depends on several critical project factors:

- Power Source Availability: Use electric pumps where grid power is accessible; opt for hydraulic units where only heavy equipment or generators are available.

- Environmental Conditions: Hydraulic pumps perform better in extreme environments, including hazardous zones or areas with poor infrastructure.

- Mobility Needs: For mobile dredging or equipment-mounted applications, hydraulic submersible slurry pumps offer unmatched flexibility. Stationary or automated installations benefit more from electric models due to their simplicity and lower operational costs.

Key Factors in Sizing a Submersible Slurry Pump

Proper sizing of a submersible slurry pump is essential to ensure performance, longevity, and operational efficiency. Oversized or undersized pumps can result in excessive energy use, premature wear, or even system failure. The following key factors must be carefully evaluated during the sizing process.

Flow Rate Requirements

The first step in sizing a submersible slurry pump is determining the desired flow rate, typically measured in gallons per minute (GPM) or cubic meters per hour (m³/h). This figure represents the volume of slurry that must be moved within a given timeframe to meet project or process requirements. Accurate flow rate calculations should consider the total volume of material, the desired timeframe, and any variability in the feed source or discharge destination.

Head and Pressure

To ensure a pump can overcome elevation differences and system resistance, it’s important to calculate the Total Dynamic Head (TDH). TDH consists of:

- Static Head: The vertical distance the slurry must be lifted.

- Friction Loss: Caused by the resistance in hoses, pipes, bends, and fittings.

- Velocity Head and Minor Losses: Resulting from turbulent flow and directional changes.

By understanding these elements, engineers can select a submersible slurry pump with enough pressure capacity to maintain efficient and continuous flow under real-world operating conditions.

Slurry Characteristics

One of the most critical sizing factors is the composition of the slurry. Key variables include:

- Particle Size: Larger solids require pumps with robust impellers and clearances.

- Density: Higher density increases the required power and wear on pump components.

- Viscosity: Thicker slurries are harder to move and demand more torque.

- Abrasiveness: Highly abrasive slurries accelerate wear, making material selection vital.

The slurry’s concentration by weight or volume also affects flow resistance and energy requirements. Misjudging these variables can lead to cavitation, clogged impellers, or excessive downtime.

Operating Environment

The physical and chemical conditions in where the submersible slurry pump operates also influence sizing and configuration. Key considerations include:

- Depth of Submersion: Deeper placement requires pumps with better pressure handling and sealing.

- Temperature: High temperatures can affect motor performance and material integrity.

- pH Levels and Chemical Content: Corrosive slurries necessitate pumps made from chemically resistant materials.

- Presence of Oils or Hydrocarbons: These can impact seal performance and motor cooling.

Power Source Constraints

Finally, the availability and type of power source play a major role in pump selection.

- Electric Submersible Slurry Pump: Ideal when stable grid or generator power is accessible. These pumps are easier to automate and require less maintenance.

- Hydraulic Submersible Slurry Pump: Suited for remote sites or mobile operations where electric power is limited. They offer high torque and are often integrated with heavy machinery like excavators.

Configuration Considerations

Choosing the right configuration for your submersible slurry pump is just as important as proper sizing. From impeller design to seal selection and monitoring systems, each component must be matched to your operating environment and slurry type to ensure consistent performance and long service life.

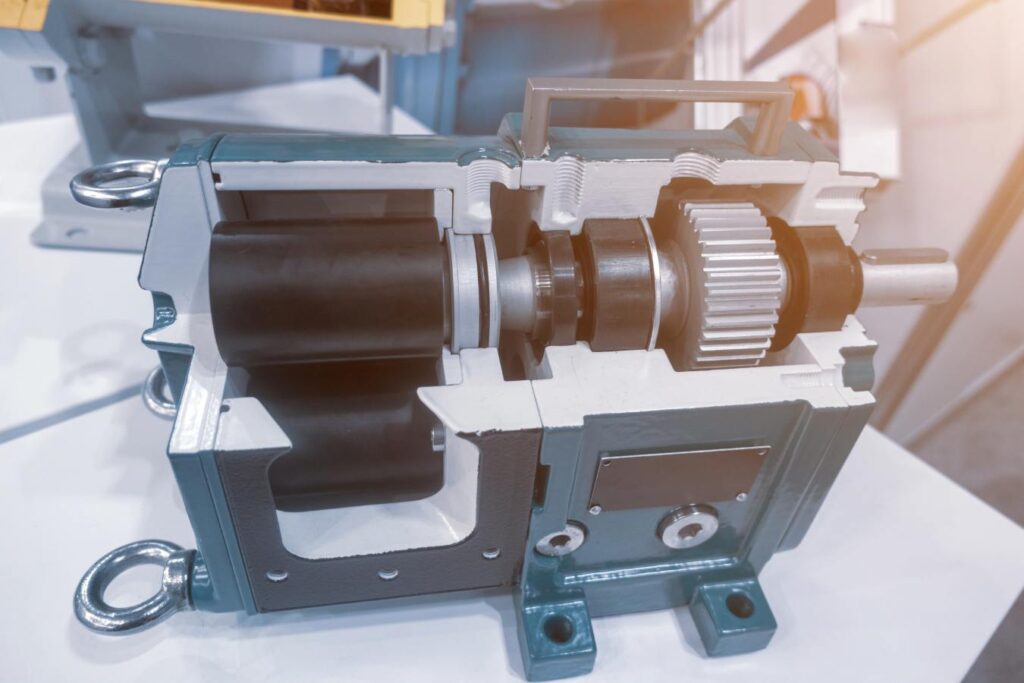

Pump Design Options

Impeller Type is a major factor in determining how effectively a submersible slurry pump can move solids:

- Open Impellers are ideal for handling slurries with large or fibrous solids. They are less prone to clogging and easier to maintain, but slightly less efficient.

- Closed Impellers offer better efficiency and are suited for fine, abrasive slurries, but they are more vulnerable to blockages if oversized solids are present.

Agitators, cutter heads, and mixers are often required in high-solid or settled slurry applications. Agitators help keep solids suspended, while cutter heads are essential in dredging or mining applications where compacted material needs to be broken apart before pumping. These features are particularly common in hydraulic submersible slurry pump configurations due to their high torque and rugged design.

Pump Materials

Material selection directly affects the durability of the pump in abrasive and corrosive environments. Common options include:

- Abrasion-resistant alloys like high-chrome iron for handling coarse or sharp solids.

- Elastomers and rubber-lined components to absorb impact and reduce internal wear.

- Corrosion-resistant coatings for chemical-laden or acidic slurries.

In both electric submersible slurry pumps and hydraulic variants, selecting the right materials reduces the need for frequent maintenance and extends service intervals.

Discharge Configuration

Submersible slurry pumps are available with either:

- Vertical Discharge: Simplifies vertical lift applications and saves space in narrow pits or sumps.

- Horizontal Discharge: Useful for routing flow laterally in trench or channel applications.

The discharge direction impacts how you design your piping layout, including the placement of elbows, reducers, and check valves. Proper configuration minimizes flow resistance and helps avoid backpressure, which can reduce pump efficiency.

Sealing Mechanisms

Slurry applications pose a significant sealing challenge due to the constant presence of abrasive and corrosive particles. High-performance seals are necessary to prevent fluid ingress into the motor housing. Key options include:

- Mechanical Seals: Standard in most pumps, offering a balance between cost and reliability.

- Double Mechanical Seals: Essential in harsh or high-pressure environments. These provide a secondary barrier and are often paired with seal-flush systems to extend service life.

Double-sealing systems are highly recommended in hydraulic submersible slurry pump setups due to their exposure to volatile or aggressive slurry environments.

Control Systems and Monitoring

Modern submersible slurry pump installations benefit from advanced monitoring and control options:

- Remote Monitoring: Enables operators to check pump performance and troubleshoot issues without being on-site.

- Pressure Sensors: Help detect blockages or cavitation early, preventing system failures.

- Variable Frequency Drives (VFDs): Adjust motor speed based on flow demand, reducing energy consumption and extending equipment life.

Installation Best Practices

Proper installation is crucial to maximizing the performance and longevity of a submersible slurry pump. Whether deploying an electric submersible slurry pump in an industrial setting or a hydraulic submersible slurry pump for remote dredging, following established best practices ensures safe and efficient operation under heavy-duty conditions.

Pump Positioning

Correct pump positioning directly affects efficiency and wear. The submersible slurry pump must be installed at an appropriate depth to ensure it remains fully submerged during operation. Insufficient submersion can lead to overheating or cavitation, while excessive depth may exceed the pump’s pressure handling limits.

Anchoring is equally important. Pumps should be securely positioned on a stable base—either suspended, skid-mounted, or placed on a platform—to prevent vibration and movement caused by slurry turbulence. Orientation matters too: the pump intake should face the highest slurry concentration zone to optimize solids intake while avoiding suction blockages.

Discharge Line Considerations

Choosing the right discharge system minimizes energy loss and ensures smooth slurry transport. Both hose and pipe options are used, depending on the project scope and flexibility requirements:

- Flexible discharge hoses are common in mobile operations using hydraulic submersible slurry pumps, allowing for rapid setup and adjustment.

- Rigid piping systems are typically used with electric submersible slurry pumps in permanent installations to maintain consistent flow paths.

Proper routing is essential to reduce backpressure and friction losses. Minimize the number of sharp bends and avoid sudden diameter transitions to maintain steady flow and prevent pressure build-up that could damage the pump or system.

Safety Protocols

Handling abrasive, high-solid content slurries introduces several safety risks. Operators must implement and follow protocols that protect both personnel and equipment. These include:

- Emergency shutoff systems are used to stop pump operation during blockages, overloads, or unexpected power failures.

- Regular inspection and access points to perform maintenance without complete disassembly.

- Protective barriers or enclosures for submerged pumps in high-traffic or hazardous areas.

Both electric submersible slurry pumps and hydraulic submersible slurry pumps should be equipped with safety interlocks, thermal sensors, and backup shutoff controls to mitigate operational risks in demanding environments.

Common Mistakes in Sizing and Configuring Submersible Slurry Pumps

Avoiding common mistakes during the selection and setup of a submersible slurry pump is essential to ensure reliable performance and minimize costly downtime. Whether you’re using an electric submersible slurry pump in a fixed plant or a hydraulic submersible slurry pump on a mobile dredging unit, precision in sizing and configuration is key.

Oversizing or Undersizing the Pump

One of the most frequent errors is choosing a pump that is either too large or too small for the job. Oversizing a submersible slurry pump can lead to unnecessary energy consumption, excessive wear, and higher capital costs. On the other hand, undersizing the pump results in inadequate flow capacity, leading to clogging, overheating, or failure to meet production targets. Accurate calculations of flow rate, total dynamic head, and solids concentration are essential for proper sizing.

Ignoring Slurry Abrasiveness and Composition

Not accounting for the abrasive and corrosive nature of the slurry is a critical oversight. Slurry containing sharp, coarse, or chemically aggressive particles can rapidly degrade internal components like impellers, liners, and seals. Both electric submersible slurry pumps and hydraulic submersible slurry pumps must be selected with materials suited for the specific slurry composition, such as high-chrome alloys or elastomer linings. Failing to match pump materials to the slurry’s characteristics significantly shortens equipment lifespan.

Choosing the Wrong Pump Type (Electric vs. Hydraulic)

Selecting between an electric submersible slurry pump and a hydraulic submersible slurry pump should be based on jobsite conditions, power availability, and mobility needs. Electric models are more efficient for stationary, grid-connected environments, while hydraulic pumps excel in remote or high-mobility applications where ruggedness and high torque are needed. A mismatch in pump type can result in operational inefficiencies, increased maintenance, or power compatibility issues.

Skipping Seal and Impeller Considerations

Seal failure is a leading cause of downtime in slurry pumping. Overlooking the need for double mechanical seals in harsh environments exposes the pump to slurry ingress and motor damage. Similarly, ignoring impeller design—whether open or closed—can lead to poor solids handling, blockages, or excessive wear. Properly configured sealing systems and impellers tailored to the slurry characteristics are vital for dependable, long-term operation.

Maintenance and Longevity Tips

Extending the operational life of a submersible slurry pump requires a proactive maintenance strategy. These pumps often operate in abrasive, high-solid environments that accelerate wear and tear. Whether you’re using an electric submersible slurry pump for stationary applications or a hydraulic submersible slurry pump for mobile dredging or dewatering, following routine maintenance best practices helps avoid unplanned downtime and expensive repairs.

Regular Inspection Intervals

Establishing scheduled inspection intervals is crucial for early detection of wear or component failure. Routine visual checks, vibration monitoring, and pressure readings should be part of every maintenance plan. Regular assessments of motor performance, noise levels, and flow consistency can reveal hidden issues before they evolve into major problems.

Seal and Impeller Wear Monitoring

Mechanical seals and impellers are among the most stressed components in any submersible slurry pump system. Due to constant contact with abrasive slurries, these parts should be frequently checked for signs of wear, pitting, or cracking. In both electric submersible slurry pumps and hydraulic submersible slurry pumps, worn seals can allow slurry ingress, damaging the motor or hydraulic components. At the same time, a degraded impeller reduces pump efficiency and increases energy usage.

Avoiding Cavitation and Overheating

Cavitation occurs when air bubbles form in the pump due to improper submersion, excessive suction lift, or incorrect flow rates. This phenomenon can cause severe internal damage. Ensure the pump is fully submerged at all times and that operating conditions align with the pump’s performance curve. Overheating can also occur when a submersible slurry pump runs dry or the cooling system is blocked. Monitoring fluid levels and temperature is key to preventing heat-related failures.

Cleaning and Flushing Procedures for Prolonged Pump Life

After each job cycle—or more frequently in high-solid or chemical-laden environments—it’s essential to perform a complete cleaning and flushing of the pump system. Removing residual slurry prevents internal buildup, corrosion, and blockages. For hydraulic submersible slurry pumps, also inspect hydraulic fluid levels and lines to ensure they’re free from contamination. In electric submersible slurry pumps, check electrical connections and cooling jackets for slurry intrusion or debris buildup.

Conclusion

A well-chosen and properly configured submersible slurry pump can make the difference between consistent, low-maintenance performance and frequent operational headaches. From selecting between hydraulic and electric submersible slurry pumps to calculating flow rate, understanding slurry composition, and implementing preventative maintenance, each decision directly impacts the system’s efficiency and durability. By applying the best practices outlined in this guide, operators can reduce downtime, extend equipment life, and ensure optimal pumping performance across a wide range of challenging applications.